Custom-Molded Orthotic System

Foot Tech

Mini-Lab System

Custom-Molded Orthotics in 30 minutes!

The Foot Tech Custom Molded Orthotic System (Mini-Lab)

The Foot Tech Mini-Lab Custom Molded Orthotic System helps medical professionals treat most foot problems efficiently and profitably, on site.

The system allows medical professionals to achieve 100% control of patient treatment while fabricating a shock absorbing, anatomically correct, custom-molded orthotic in 30 minutes, right in their facility.

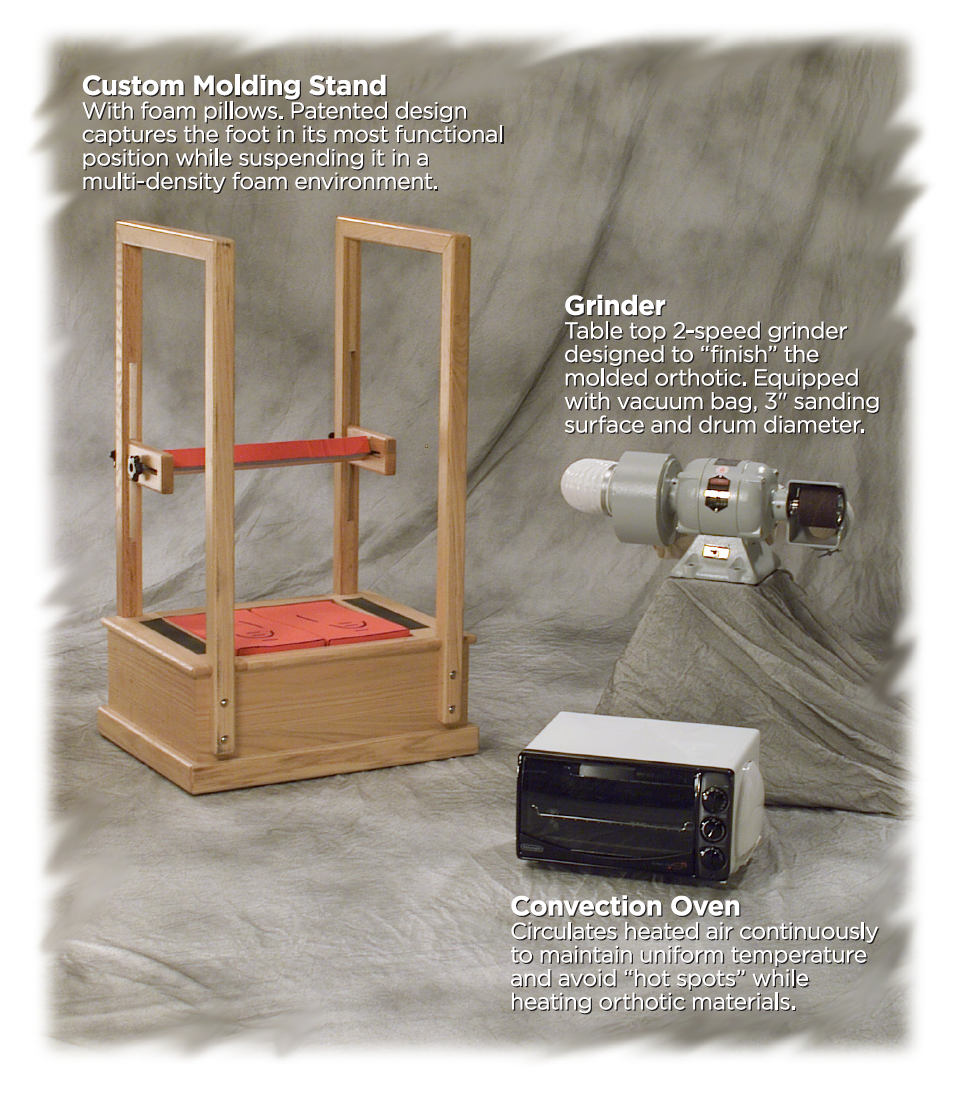

The system consists of an array of specially designed orthotic blanks and half-sole add-ons, a molding stand with specially designed impression pillows, a convection oven to heat the orthotic blanks, a grinder to produce a neat and consistent finished look to the orthotics, and various additional posting materials.

CUSTOM MOLDED ORTHOTIC SYSTEM>

What Makes the Foot Tech Mini-Lab Custom Molded Orthotic System Unique

- Efficient and profitable treatment system

- Fast – custom orthotics in 30 minutes

- Accurate – custom mold of the foot

- Allows treatment of most foot and ankle pathologies

- Flexibility for modification

- Fits in most footwear

System Benefits

The Foot Tech Mini-Lab System allows the technician to fabricate problem-solving devices as well as achieve functional control through the selection of add-on materials of varying densities. Through the patented direct-molding process, the practitioner is able to capture the foot in its most functional position, which is usually in or about subtalar neutral, by suspending the patient’s foot in a multi-density foam environment.

This molding process allows the practitioner to simulate the foot’s position in the mid-stance phase of the gait cycle, allowing the practitioner to control and/or correct alignment of the lower kinetic chain. Thus, the structural changes that take place between non-weight bearing and weight bearing (splaying, elongation, locking of the forefoot, etc.) are addressed while the foot’s alignment is controlled.

As a result, an effective orthotic can be formed quickly and easily, which provides an excellent device fulfilling the patient’s biomechanical needs and achieving Dynamic Alignment™.

Pathologies Treated

Foot Tech Mini-Lab System provides excellent relief from a wide variety of foot pathologies and related maladies:

Plantar Fasciitis

Patellofemoral Pain Syndrome

Metatarsalgia

Shin Splints

Stress Fractures

Plantar Pressures (Blisters, Callouses, etc.)

Ankle Sprains

Heel Pain Syndrome

Turf Toe Injuries

Hallux Limitus/Rigidus

Sesamoiditis

Hallux Valgus

Forefoot Lesions

Metatarsal Stress Fractures

How the Mini-Lab System Works

The Custom Molding Process

Foot Tech Mini-Lab Custom Molding Process – Step 1

An orthotic blank is chosen based on the patients' clinical evaluation. The orthotic blank is then heated in a convection oven at 250°F for 3-4 minutes until the inner vinylplex core becomes malleable.

Foot Tech Mini-Lab Custom Molding Process – Step 2

The heated blank is placed on the suspension pillows of the molding stand and the patient's feet are placed on the heated orthotic blanks. Use the markings on top of each pillow to assist in determining proper heel placement of the heated orthotics.

Foot Tech Mini-Lab Custom Molding Process – Step 3

Position the adjustable knee bar of the molding stand to a 45° angle to the patient's patellas. The patient's knees are placed against the knee bar, simulating mid-stance.

Foot Tech Mini-Lab Custom Molding Process – Step 4

The practitioner then palpates the subtalar joint and positions the patient in their most functional position, which is usually in or about subtalar neutral, utilizing the principles of tri-planar motion. The patient should remain in this position for approximately...

How the Mini-Lab System Works

The Finishing Process – Building Rigidity and Stability

Foot Tech Mini-Lab Finishing Process Step 1

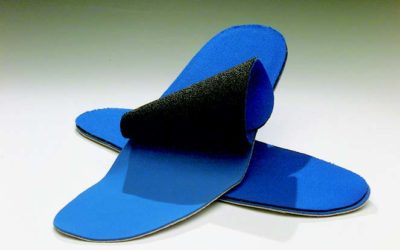

An appropriate half-sole add-on is selected (available in three densities) based on the desired rigidity and control reguired for the patient. The application of the half-sole add-on to the molded orthotic allows the practitioner to determine the amount of resistive...

Foot Tech Mini-Lab Finishing Process Step 2

Excessive material on the sides and bottom of the half-sole add-on is removed with the grinder. This process allows the practitioner to grind functional angles in the orthotic as well as achieve a level plane on the bottom surface.

Foot Tech Mini-Lab Finishing Process Step 3

When grinding is completed, the product can then be easily posted on the rearfoot or the forefoot to achieve the desired biomechanical effects. This completes the Finishing process.

Foot Tech Product Descriptions

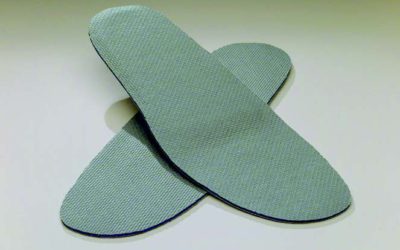

Cambrelle Orthotic (FNCN / FNCK / MNCN / MNCK)

Non-woven top surface designed to absorb three times its weight in perspiration. Excellent breathability, resistance to odor, abrasion, and piling for strength, durability and easy care. Recommended for moderate activity level. Available with thin 1/16" or thick...

Athletic Orthotic (MNAR / FNAR / MNR / FNR)

A durable nylon surface able to withstand heavy athletic use. Material has ability to move in all directions, reducing friction which can result in tissue breakdown. Non-absorbent and cleans easily. Recommended for high activity level; e.g. athletes. Available...

Plastazote (Accommodative) Orthotic (MNP / FNP)

A softer, cushioned orthotic designed for the "at-risk" foot: diabetic, neurovascular compromised, peripheral neuropathy, or arthritic. Available with or without* core material for patients who cannot tolerate even semi-rigid support. Incorporates Poron®...

Dress Cambrelle Orthotic (FDCN / MDCN)

Same qualities as described in Cambrelle orthotic. These 3/4 (or sulcus) length orthotics are designed for use in lower volume footwear. Available with thin 1/16" Poron®.

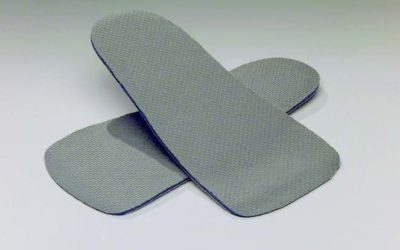

Forefoot Split Orthotic (FNBF / MNBF)

A durable blue nylon surface identifies this product. Nylon material moves in all directions, reducing friction. Non-absorbent and cleans easily. Forefoot area is not glued down, allowing metatarsal pads, special padding or accommodate depressions to be added and...

Metatarsal Pads and Bars

(used with forefoot split) Designed to transfer pressure from the metatarsal heads to the metatarsal shaft. Made of soft foam to provide comfort to the patient. Available in soft and firm and varying sizes.

Ucolite / EVA Footwear (FULN / MULN / FULK / MULK)

Durable Ucolite / EVA top cover with choice of thin 1/16" or thick 1/8" Poron® and a leather bottom cover.

Pediatric Orthotics (PNR / PNAR)

Cambrelle top surface. Sizes range from children's size 8 through youth's size 4. Available with thin 1/16" or thick 1/8" Poron®.

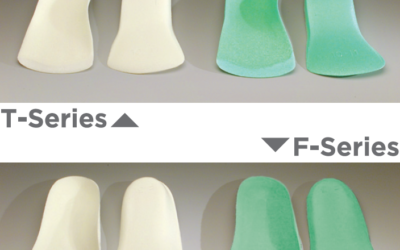

Half-Sole Add-Ons

Molded polyethylene foam added to the molded orthotic to control rigidity, stability and angle of the finished orthotic. Available in 3 densities - from soft to rigid - and 2 styles: T-Series - Available in White rigid and Green firm; five sizes each for male and...

Heel Cushion

Special Order. Designed to provide immediate relief to the patient suffering from heel pain, yet in need of orthotic support. Core material is cut away in the heel area and replaced with an additional 1/8" of Poron® shock-absorbing material for extra cushioning. ...

Rearfoot Posting (HW)

Rearfoot wedges designed for posting calcaneus or rearfoot. Formed rubber material. Available in three sizes: 2°, 3°, & 4°.

Arch Supports

Provides additional support to the midfoot or arch after the orthotic blank has been molded and prior to adding the half-sole add-on. Available in three types of materials, from soft to rigid support: Poron®, My-T-Lite and Thermal Cork; and in four sizes.

Heel Lifts

Constructed from firm, lightweight material with minimum compression. Designed for leg-length discrepancies. Available in two thicknesses: 3/16" and 1/4"; and in four sizes.

Forefoot Posting (FW2 / FW4)

Nickleplast material designed for posting forefoot - tapered to 2° and 4°.

Additional Specialty Orthotics

|

|

Any questions about our products can be directed to our customer service department at:

1-800-969-3668

Phone

info@wrymark.com

Business Hours

M-F: 8am - 5pm (CST)

Location

11833 Westline Industrial Drive

St. Louis, MO 63146